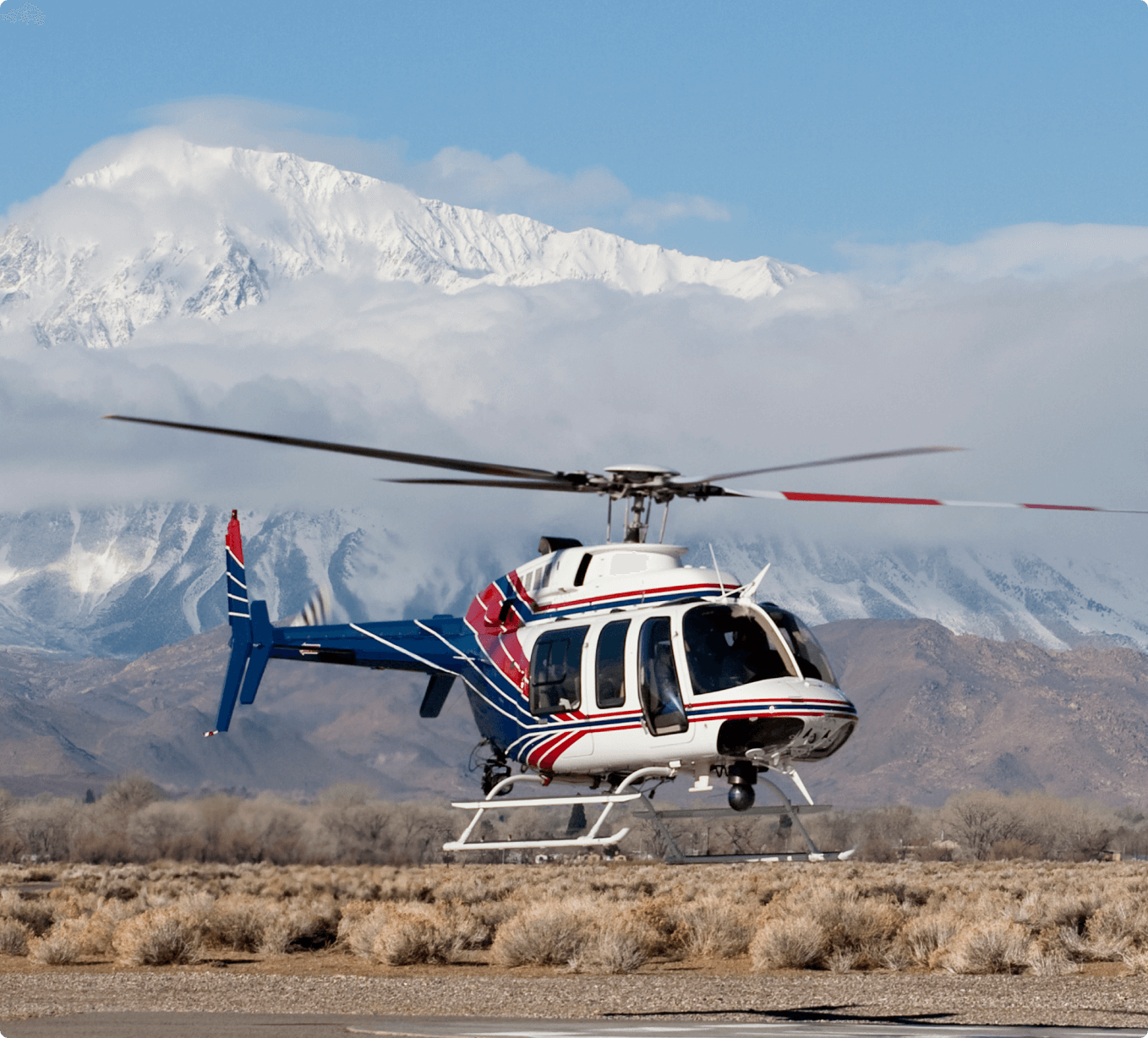

Proven, Reliable

Cabin Heat

High performance, low maintenance bleed air heat systems.

Designed to deliver highly reliable heat into the aircraft, our bleed air heater systems have been trusted for unparalleled reliability and low maintenance for over forty years.

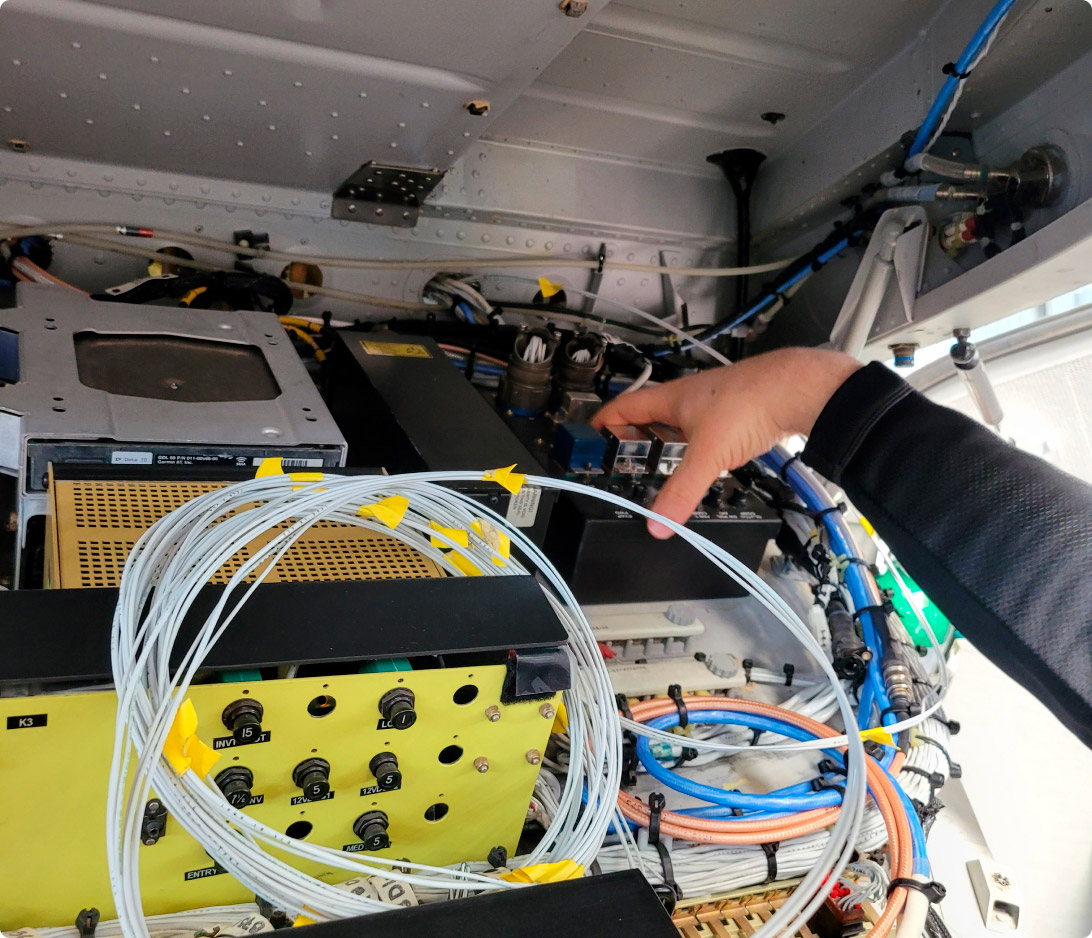

How it Works

The bleed air heating system takes that heat generated off of the aircraft engine and reroutes it into the cabin and the cockpit through stainless steel plumbing connected directly to the aircraft’s engine compressor scroll.

This bleed air heat is also utilized to defrost and defog the windshield and the chin bubble.

We can also provide cabin air heat using our electrical heaters. Commanded directly from our system controller or from the aircraft, our heaters are composed of PTC elements, integrated fan, temperature sensor and switches for proper thermal capacity output and control.

Highly reliable heat:

The bleed air heating system’s stainless steel plumbing and injectors eliminate moving parts, minimizing deterioration and the need to replacement parts. These factors combine to consistently deliver highly reliable, proven performance.

Low noise level:

The air heating systems maintain a comfortable, low noise level.

Air Heaters

stainless steel system that reliably and efficiently moves hot air from the compressor scroll down into the cockpit, and then emits that hot air via a series of proprietary cabin heat ejectors controlled through a simple on/off gate valve.

a market leader in terms of heat, the Arctic cabin heater was engineered for customers flying in the harshest winter conditions. Utilizing the same technology as the standard heater, the Arctic cabin heater provides larger capacity and more power up to negative 40 degrees Fahrenheit.